Rose Druck in figures

Family business

established

Almost 180 years ago, Wilhelm Wenzel Klambt laid the foundation for one of Germany's most traditional printing companies by publishing a magazine.

home in Landau

The plant in Landau has existed since 1993, and since 2011 it has been the home of the family-owned company Rose Druck GmbH.

employees

A team that stands together: from trainees to 50 years of service, from all-rounders to specialists, 14 nations and all with heart and hand.

pallets per day

Thanks to our own logistics, we get around 200 pallets of our customers' advertising messages on their way every day.

tons of paper per day

Every day, we process 165 tons of paper into inserts, brochures & magazines. This makes us an efficient competitor for web offset products.

rotary presses

In April 2021, after only one year of construction and installation, we put a third rotary press, type KBA TR 6 B, into operation.

Family business

established

home in Landau

employees

pallets per day

tons of paper per day

rotary presses

What we are made of

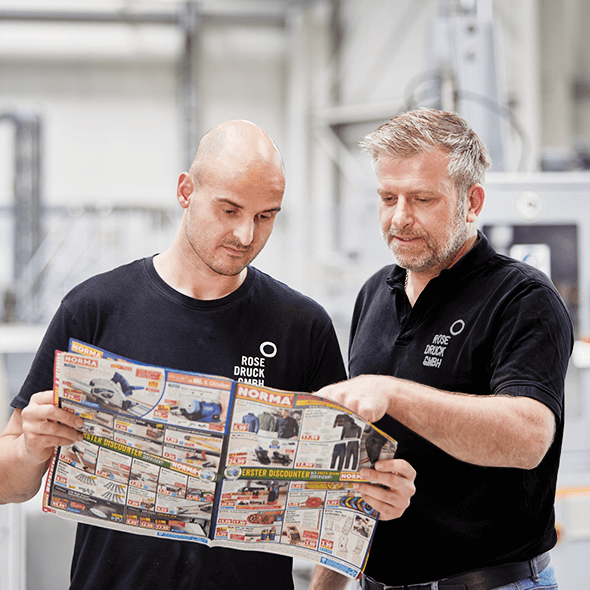

Reliability is the top priority at Rose Druck, and the same goes for commitment, trust, quality. Our customers as well as our employees and partners know they can count on us. Such values are not just words, we walk the talk.

.

Loads of experience, commitment and team spirit – this is what our 135 employees stand for. Company seniority is the standard at Rose Druck, not the exception. Hired labor? Unknown to us. Many of our staff already represent their second generation with Rose Druck. We always offer exciting opportunities to young, committed talents and trainees.

We always keep looking for new opportunities. This is why we push the limits of our machines and break technical barriers. And successfully so – some of our in-line subsequent processing was developed in-house. The R-Cover specialty product is our own patent. We are currently doing research on the use of water-based ink to safeguard the future of our technology in a sustainable way.

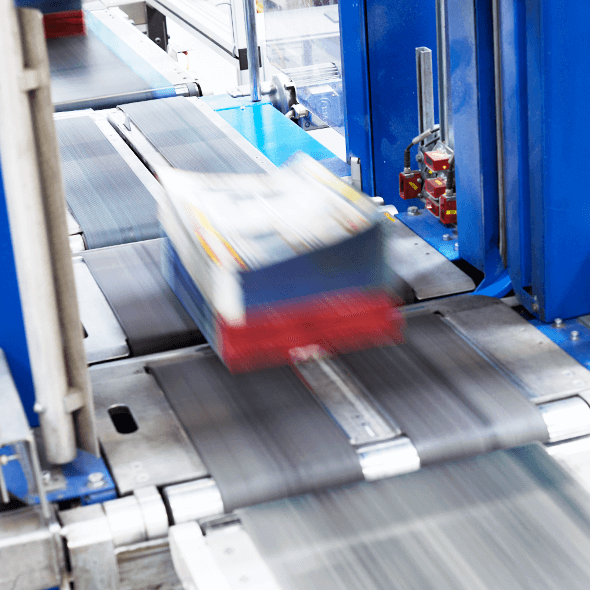

We will enthrall you with our technical opportunities. With our three surprisingly flexible gravure rotaries Rose Druck produces any type of magazine, advertising insert or catalogue quickly and accurately. Our strength: We print all kinds of different formats at high speed with numerous options processed in-line.

Our mission

Being a valuable and reliable partner to our customers, employees and suppliers is our goal. With great commitment, skill, innovative strength and sustainability, we want to lead our technology into the future and thus continue the almost 180-year history of our company.

Our history

We are live - since 1843. Rose Druck is a family business with almost 180 years of tradition. Our history goes back to a 19th century press pioneer: Wilhelm Wenzel Klambt, great-great-grandfather of today's managing director Bernd Rose, founded Klambt Verlag in 1843, which became Klambt Druck GmbH in 1955.

1843

Book lender and author Wilhelm Wenzel Klambt starts his magazine "Der Hausfreund – eine Wochenschrift für alle Stände" in the small Silesian town of Neurode. Quite a daring venture at the time – the press is still in its infancy, publishers are subject to strict censorship, and printing means painstaking work. Klambt starts by producing 500 copies per day using a simple hand press.

1882

Wilhelm Wenzel Klambt sells the publishing house to his son-in-law Georg Rose. Under his leadership the "Hausfreund" makes its breakthrough from a regional magazine to a weekly family magazine popular all over Germany. The Klambt publishing house becomes a significant company with several sites in Germany printing magazines, calendars and books with circulations of several million.

1945

In World War II the company loses its head office in Neurode and almost all sites in Western Germany. Speyer is the only site left to the Rose publisher family. From here Dr. Günther Rose, Klambt’s great grandson, starts rebuilding the publishing house. It becomes the leading publishing house in the segment of family and women’s magazines. Apart from "Hausfreund" – published by Klambt media group by the name of "7 Tage" – it doesn’t take long for further titles to be published.

1955

The Klambt group expands its printing business and goes for the spin-off of this activity in 1955 already, turning it into the independent Klambt Druck GmbH.

1970

In the 1970s and 80s managing director Wolfgang Rose turns Klambt Druck into one of the most modern printing companies in Germany. Continuous innovation expands the range to include every section of printing technology. Apart from book printing and offset, gravure printing becomes one of the special lines. Printing is no longer limited to media by the Klambt group but includes books and magazines for other renowned publishing houses as well as mail order catalogues and various advertising inserts.

1992

Klambt Druck sets up a new site in Landau in the Palatinate. A state-of-the-art rotogravure printing plant is built on a greenfield site.

1996

Schlott Gruppe AG acquires Klambt Druck GmbH which is renamed to wwk druck GmbH in 1998. The initials of founder Wilhelm Wenzel Klambt live on in the company name. With Bernd Rose, the CEO of the printing group operating all over Europe, one of Klambt’s great-great-grandsons again takes the position of managing director.

2011

Following the insolvency of Schlott Gruppe AG Bernd Rose and his family take over the majority in the wwk druck rotogravure printing plant in Landau. The corporate Appl group from Wemding becomes the minority shareholder.

2018

The Rose family reacquires Appl's shares. Together with the management team consisting of Michael Roth, Tobias Kabel and Domenica Ratzel (left to right), managing director Bernd Rose is managing one of the most well-established German printing plants in the fifth generation.

2020

Rose Druck decides to add an additional rotogravure press to the Landau plant. For this purpose, a used machine from Belgium is bought, overhauled and rebuilt. Machine parts and additional units from seven European countries are used.

2021

The "pan-European" machine at Rose Druck comes on stream successfully after only 13 months of planning, construction and assembly. In addition to the expansion of production opportunities the third gravure printing press is also the basis for developing and testing other innovations at Rose Druck.

2022

In February 2022, Linn Rose will be appointed as another managing director of Rose Druck GmbH alongside Bernd Rose. This marks the beginning of the gradual transition to the 6th generation in the family business.

2023

In a further step for the future direction of the company, Tobias Kabel is appointed as an additional Managing Director of Rose Druck GmbH.

Sustainability

Sustainable and responsible entrepreneurship have always been a matter of course for us. As a family business it is in our own best interest to start thinking of the future today and safeguard it for the succeeding generations.

In 2015 the international community adopted seventeen goals for sustainable development under the umbrella of the UN. Sustainable development is defined as "a development that meets the needs of the present without compromising the ability of future generations to meet their own needs". Economic growth, social inclusion and environmental protection are interconnected and must be reconciled for the well-being of individuals and societies in the long run.

As a company, we regard these goals as a stimulus as well as support for our development. We closely observe several of these goals ourselves:

- Health and well-being – Supporting a healthy lifestyle and promoting the well-being of our employees are essential to the sustainable development of our company. This way we support cohesion, exchange, know-how transfer and innovat.

- Quality education – We regard high-quality education and training as well as life-long learning as a sustainable investment in multiple ways; investing in the personal development of our employees and in the know-how within the company which can trigger successful product developments and innovation.

- Gender equality - In a technical branch of industry male-dominated by tradition, it still proves difficult to reach a gender balance. This is why we welcome any type of diversity as a valuable gain opening up new prospects, providing new input and promoting openness.

- Sustainable growth in industry, innovation and infrastructure – For several years we have been working on an innovation with our research project on water-based ink in gravure printing. This does not only provide a sustainable prospect for ourselves as a company but would make our technology more resource- and eco-friendly.

- Responsible consumption and sustainable production – In our company we consistently strive for saving resources and tapping the total potential of recycling.

For more information on the UN sustainable development goals please go to: www.un.org/sustainabledevelopment/sustainable-development-goals/

Since 2018 we have been working on an internal R&D project on using water-based ink in publication gravure.

The successful switch from solvent-based to water-based ink would open up extremely positive ecological and attractive economic opportunities for our printing processes. Several trials and series of tests show successful results. We check the technical and economic feasibility, aiming at using the process ourselves and commercializing it. We’ll keep you posted!

Our focus is on avoiding waste and reducing the consumption of resources wherever possible as well as recycling. Rose Druck recycles most of the resources used in production.

We own an extremely high number of cylinders – about 1000 – with various circumferences. Our customers benefit from the fine grading of cylinder circumferences as we can realize almost any format with extremely little paper waste. We maximize the use of the paper webs, thus generally avoiding waste.

An elaborate recovery process is used to extract the solvent contained in printing inks from the waste air, recycle it and use it in paint factories for the production of new ink. The process heat of the solvent recovery is used to generate steam for our printing processes and for heating our premises.

Since 2011 Rose Druck has been committed to the highest quality requirements in terms of eco-friendly operations and sustainability every year. EMAS (Eco-Management and Audit Scheme) is the most exacting eco-management system in the world, developed by the EU for companies submitting themselves to a voluntary environmental assessment and certification.

Based on regular audits Rose Druck keeps improving its energy and resource efficiencies to protect the environment. External auditors collect, examine and document the environmentally relevant company data - from energy consumption, emissions, disposal & recycling to legal compliance.

For further information on EMAS, please go to: www.emas.de

You can download our environmental statement here: Download Umwelterklärung (PDF)

You can download our Environmental Report 2023 (Only german version available) directly here or find it in our download area.

![]()

The EU Ecolabel is awarded to "products and services that have a lower environmental impact than comparable products. The EU Ecolabel is intended to enable consumers to identify more environmentally friendly and healthier products."

Apart from quality and price, the environmental impact of a product has become the key consideration when buying a product.

We are one of the first printing companies in Europe to be awarded this certification and are thus authorized to attach the EU Ecolabel to our print products, proving their high degree of environmental compatibility.

We are proud of supplying our customers with certified, eco-friendly and sustainable print products.

![]()

Based on the FSC® (FSC® C107330) and PEFC (PEFC/04-31-1881) certifications for the sustainable handling of paper and timber products, our customers can use paper products from sustainable forest management, thus actively promoting environmental protection.

For more information, please go to:

How can we help?

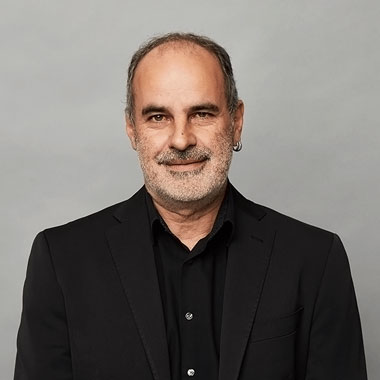

Managing Director

Bernd Rose

+49 6341 590 400

Managing Director

Linn Rose

+49 6341 590 430

Head of Operations

Michael Roth

+49 6341 590 410